Description

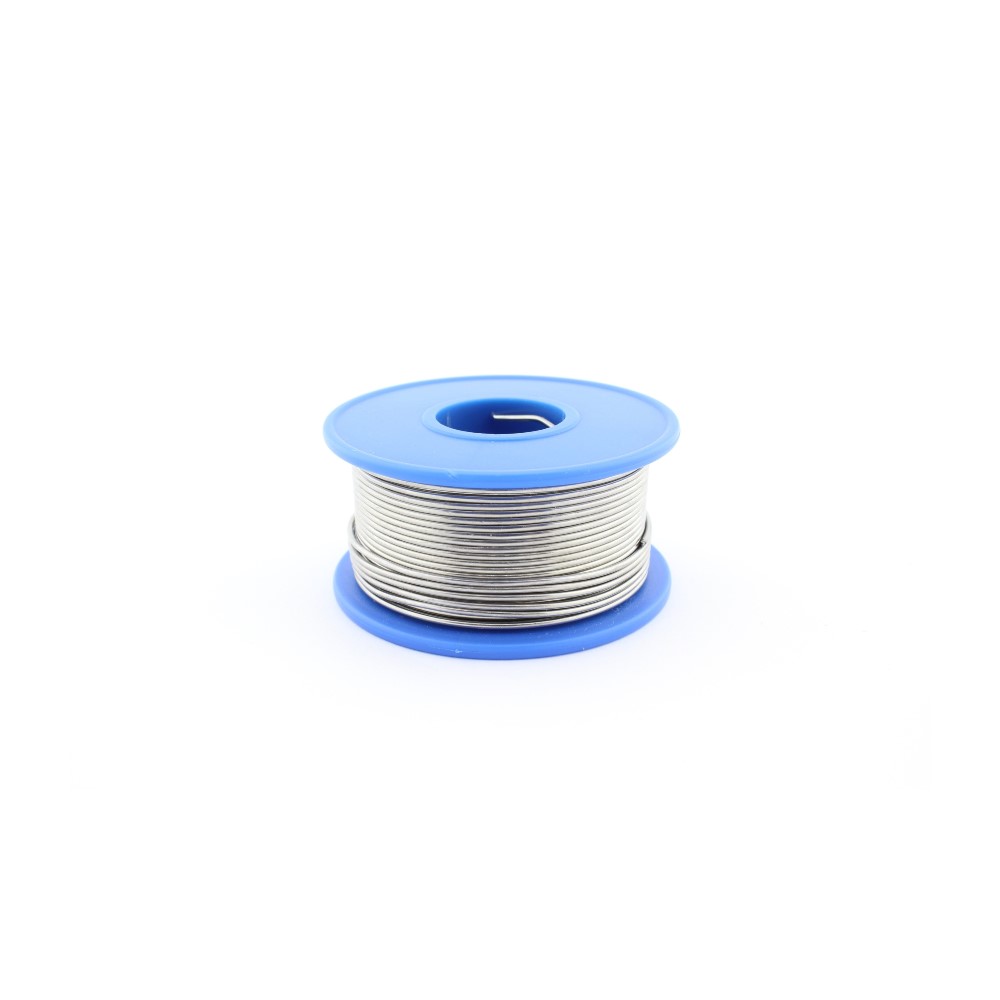

Using a Soldering iron as a source of heat, soldering lead is applied for connecting an electrically conductive element (such as a terminal clip, or a connector contact, or a semiconductor chip holder terminal) to a metallic area on a substrate or the like.

Soldering lead is a metal alloy usually made of tin and lead which is melted using a Soldering iron. The soldering iron is heated to temperatures above 600 degrees Fahrenheit which then cools to create a strong electrical bond.

Types:

- Lead-based solder – Solder based on lead was universally used in the past. It was made of a mixture of tin and lead. Usually a 60/40 (tin/lead) mix, that melts at around 180-190C degrees. Because lead has some damaging effects to our health, the industry is moving away from lead and towards lead-free solder.

- Lead-free solder – Lead-free solder is solder without lead. EU requires commercially available electronics to use lead-free solder (RHoS) because of the health hazards of lead. It has a higher melting point, so it is a bit harder to work with, but usually not a problem.